Dr. Martens shoes have become a timeless symbol of rebellion, individuality, and self-expression. From punk rock concerts to fashion runways, these iconic boots have always managed to make a statement. But have you ever wondered where Dr. Martens are made? In this article, we will take you on a journey to explore the origins and manufacturing process behind these beloved shoes.

Feet in ridiculous pain and you're slowly loosing the will to live? Try Break Me In Daddy, the easiest way to break in your new Doc Martens without making your feet look like grated cheese. Lactose, cute toes. Find out more →

The manufacturing of Dr. Martens shoes is deeply rooted in history. It all started back in 1901, when Dr. Klaus Märtens, a German army doctor, designed a pair of boots to help him recover from a foot injury. These boots featured an air-cushioned sole, providing superior comfort and support. This innovative design caught the attention of British entrepreneur Bill Griggs, who partnered with Märtens to create what we now know as the iconic Dr. Martens brand.

Today, Dr. Martens shoes are made in various locations around the globe. One of the primary manufacturing facilities is located in the United Kingdom, where the brand's roots lie. Here, skilled craftsmen work meticulously to bring each pair of Dr. Martens shoes to life. From cutting and shaping the leather to attaching the iconic yellow stitching, every step of the process is done with extreme precision and attention to detail.

In addition to the UK, Dr. Martens also has manufacturing facilities in Asia, specifically in China and Thailand. These facilities employ a combination of traditional handcrafting techniques and modern machinery to produce high-quality shoes that adhere to the brand's standards.

What sets Dr. Martens apart is the use of premium materials. The leather used in their shoes is sourced from top-quality suppliers, ensuring durability and longevity. The distinctive air-cushioned sole, a hallmark of Dr. Martens, is made from a unique blend of materials that provide exceptional comfort and shock absorption.

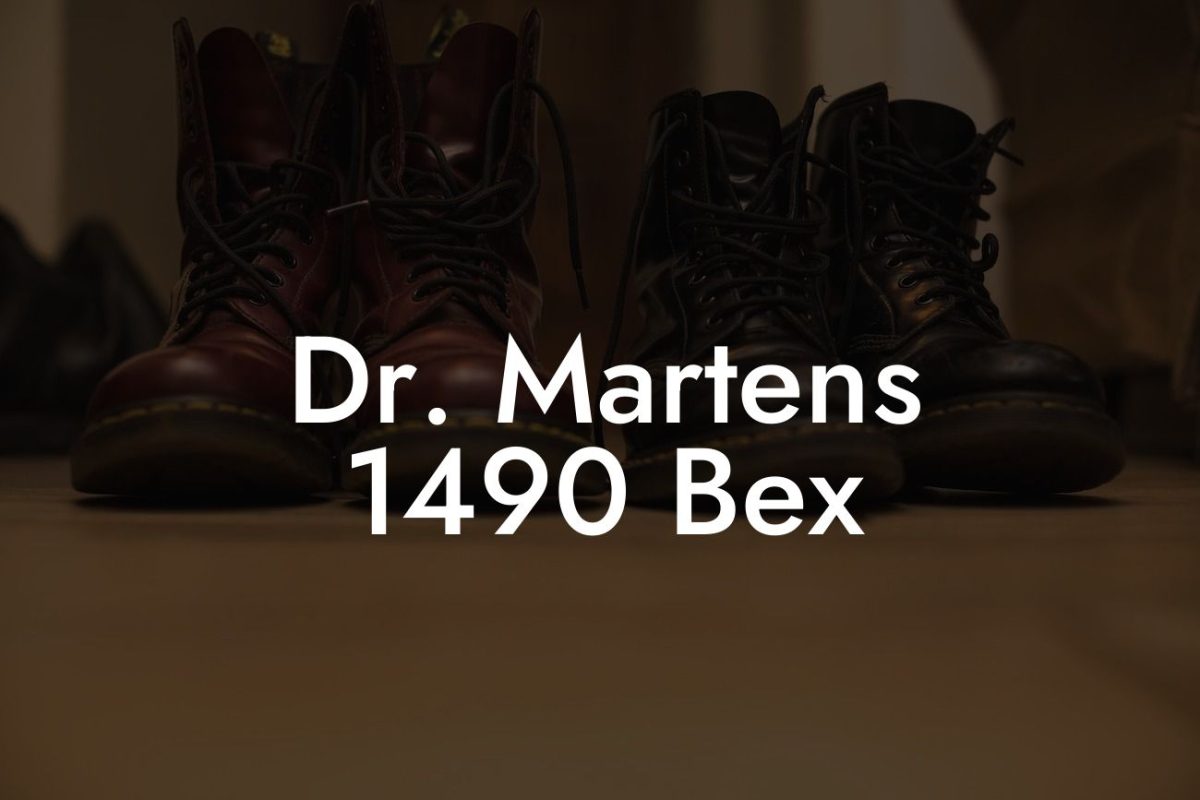

Where Dr Martens Are Made Example

Let's take a closer look at the manufacturing process of Dr. Martens shoes. The leather used in the shoes goes through a rigorous selection process to ensure only the best hides are chosen. Skilled craftsmen then cut the leather into precise shapes, creating the various parts of the shoe, such as the upper, lining, and insole.

Once the leather pieces are ready, they are meticulously stitched together using the famous yellow thread. This process is done by hand, ensuring the utmost durability and strength. The iconic yellow stitching not only adds to the aesthetic appeal of the shoes but also serves as a symbol of quality craftsmanship.

After stitching, the shoes go through a process called lasting, where they are stretched and molded onto shoe lasts to achieve the desired shape. This is followed by the attachment of the air-cushioned sole, which provides superior comfort and cushioning.

As you can see, the manufacturing process of Dr. Martens shoes is a blend of tradition, craftsmanship, and innovation. Each pair is carefully made by skilled artisans, making them more than just a fashion statement. They are a testament to the brand's dedication to quality and longevity.

Now that you know more about where Dr. Martens are made and the craftsmanship that goes into creating them, be sure to explore our other guides on Break Me In Daddy. Share this article with fellow Dr. Martens enthusiasts and let them dive into the fascinating world of these iconic shoes.